Why Hot Suppressors Stick to Cold Mounts

As more and more people buy into the growing suppressor market, I’ve noticed that many folks seem to be running into some common silencer problems with increasing frequency. Whether it’s confusion over suppressor maintenance, disappointment due to gassy backpressure, or silencers that simply won’t come off supposedly “quick detach” (QD) mounts, silencer sadness seems to be common these days, even if the market itself is booming. While maintenance is mostly suppressor dependent and we’ve talked here before about gas blowback, I’ve not yet delved into the curious case of stuck silencers. Let’s take a close look at one common cause for disobedient QD mounts.

Carbon and Lead can Freeze a Suppressor

When shooting with a silencer, molten lead from the bullet/primer along with carbon left behind by burning gunpowder often build up within the suppressor’s body. As these byproducts accumulate inside the tube, they effectively weld themselves (the lead especially) to the tube and baffles. While some designs account for this buildup and work to isolate the silencer tube from the internal baffle stack, others can become so “frozen” that special tools are needed to disassemble the silencer.

In rimfire applications, this debris is especially troublesome and accumulates far faster with more invasive side-effects than centerfire use cases. As a matter of fact, most in the industry say that rifle suppressors need no servicing, as the pressure inside the silencer during use blows out much of the debris that lodges itself among the baffles. “Carbon lock” (a situation where built-up carbon deposits on the mount and silencer “fuse” the two together) certainly happens with rifle suppressors, especially those that see high round counts, but heat is an oft ignored culprit for sticky QD silencers. Fortunately, temperature-related issues are rather easily managed with a little care.

Metals Expand When Heated

If you think back to your basic high school (or middle school in many cases) chemistry class, you’ll likely remember that matter generally expands when exposed to heat energy. As the temperature of matter increases, so too does the kinetic energy within that matter’s molecules. This kinetic energy causes the average separation between molecules to grow and, thus, increases the volume of the object as a whole.

Since the steels and titanium alloys used in most suppressor bodies and mounts expand volumetrically, they grow in all directions when heated. As such, a silencer that has been removed from a rifle immediately after sustained fire will be in an expanded state relative to a suppressor or mount that remains at ambient temperature. When this (ever-so-slightly) enlarged suppressor is placed on a cool or ambient mount, it can be expected to twist on slightly farther than it would if it too were at room temperature. As the silencer cools, it contracts and further tightens itself to the mount to the point that it may become seemingly impossible to remove. This is especially true with today’s highly popular taper-style mounts, and it is the cause of considerable frustration among shooters who swap their silencers across multiple rifles.

Heat Flows from High to Low

According to Newton’s Second Law of Thermodynamics, energy flows from areas of high concentration to those of lower concentration. In our case, this means that energy from a hot silencer will begin to transfer to the mount upon attachment. Based on what we already know about thermal expansion, this heat transfer will subsequently cause our mount to expand and the silencer to contract. Eventually, the heat stored within the parts will dissipate into the atmosphere, but in the short term, we have a situation where our mount is quite literally growing inside our shrinking suppressor tube.

Now, as the two reach an equilibrium state, the directional flow of heat becomes less significant to our stuck suppressor dilemma. It is after all, the initial attachment of a hot silencer to a cold mount that gets us into the most trouble. However, the flow of energy between the two parts is important to understanding why a silencer that we mounted just a minute ago might now be firmly stuck, even if it is still warm to touch.

Different Materials have Different Coefficients of Expansion

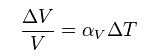

Let’s take a look at the formula for volumetric expansion:

Broken down, the equation means that the fractional change in matter’s volume is equal to the change in temperature multiplied by the coefficient of expansion for the material in question. Every material has its own coefficient of expansion, which essentially indicates the rate at which it will expand when exposed to heat.

Now that we understand how expansion occurs, it is important to realize that stainless steel has a relatively high coefficient of expansion. Compared to other popular suppressor and gun metals, like titanium and carbon steel, stainless more readily expands when heated. For reference, most stainless steels come with coefficients in the 50 µm/m-°C range while pure titanium (suppressors use titanium alloys) sits at 26 µm/m-°C and carbon steel hovers around 32 µm/m-°C. Based on these numbers, a hot stainless silencer should be expected to expand quite a bit more than a toasty titanium one.

Conclusion

Though the ability to move the silencer around to different rifles is a major selling point for “quick detach” suppressors (and rightfully so), the functionality should be used with some caution. Generally speaking, if the silencer is too hot to hold with bare hands comfortably, it is probably too warm to place on a cold muzzle device without a significant risk of sticking to the mount. This risk is even higher if the suppressor’s body and mount are both made of stainless steel, as it tends to expand more when hot than other popular metals. In short, the best course of action is to exercise a little patience and let the suppressor cool before moving it to another firearm.

Note: One popular way to keep a silencer from sticking is to apply a small amount of anti-seize to the mount and silencer. Be careful to use only enough to cover the engagement surfaces as the solution can get a bit messy. Also, take care to note that anti-seize compounds have different temperature ratings depending on the materials they contain. If you’re a very high volume shooter, your suppressor may reach as high as 1,000 degrees Fahrenheit on occasion.

If by chance, your silencer does stick to its mount, there are a number of different ways to dislodge it. The most recommended method is to use some sort of low-viscosity penetrating oil (like Liquid Wrench) that can seep between the silencer and mount. This oil is made to flow in between close-fitting parts, but some patience is needed to allow it to penetrate the interface between the mount and the suppressor fully. Sometimes, leaving the silencer drenched in oil overnight before attempting removal is the best course of action.

If penetrating oil does not work, applying heat to the silencer either by firing a few rounds through it or with a heat gun can help as well. As a general rule, hot, expanding gasses released during use cause the suppressor body to warm faster than the mount. Likewise, applying heat directly to the suppressor tube will cause it to expand some before transferring that energy to the mount.

An information security professional by day and gun blogger by night, Nathan started his firearms journey at 16 years old as a collector of C&R rifles. These days, you’re likely to find him shooting something a bit more modern – and usually equipped with a suppressor – but his passion for firearms with military heritage has never waned. Over the last five years, Nathan has written about a variety of firearms topics, including Second Amendment politics and gun and gear reviews. When he isn’t shooting or writing, Nathan nerds out over computers, 3D printing, and Star Wars.