3D Printed Guns: Catching Up with Ivan T.

After a recent Twitter dustup over a previous 3D printed firearms article led to a debate between myself and designer Ivan T., aka Ivan_Is_Back (formerly IvanTheTroll12), we both felt that the best way to clear the air would be to sit down and chat about the state of printed guns. The result was a more than 90-minute long interview and detailed look into the past, present, and future of the technology. For readability’s sake, I have split the discussion into two parts. This entry covers some of Ivan’s past work (hosted on his Keybase) and a future piece will address current projects and future developments.

Readers who are interested in a more in-depth look at 3D printed firearms should also read the Armament Research Services (ARES) report published by Ivan and co-authors G. Hays and N.R. Jenzen-Jones titled Desktop Firearms: Emergent Small Arms Craft Production Technologies.

Background

Though he grew up in a gun-owning family Ivan’s personal journey with firearms began, like many, as an acquired taste. His first shooting experience as a kid featured sporting clays and a 12-gauge Auto 5 shotgun and as he recalled, “it’s the kind of gun that will kick your teeth out.” It wasn’t necessarily enjoyable but shortly thereafter, he discovered .22 LR and from there the passion took off.

Also like many young gun enthusiasts, Ivan’s interests were driven in large part by firearms featured in popular video games, like Call of Duty. He specifically named the Hecler & Koch G11 “space gun” as an example of a firearm that helped to introduce him to a world beyond the Ruger 10/22, filled with interesting designs and high-tech materials.

By the time he reached high school, Ivan’s fascination with DIY, or what some now call “maker”, projects led him to enroll in a CAD drafting class. The skillset came naturally for him, but the class also introduced Ivan to his first 3D printer. It was an 90s era “rapid prototyping machine” but even with its limited capabilities, the seed was planted.

As a car enthusiast, Ivan used that machine to print a hood ornament and at that point he realized that “this is more than just something niche and maybe there’s some usefulness to [3D printing].” Yet in the days before the influx of affordable Chinese printers, Ivan’s options for a machine of his own were limited – and pricey. Certainly, the $2,000 RepRap and Makerbot printers of the era were well beyond most high schoolers’ budgets so he shelved his planned purchase.

After a 3D printing hiatus, Ivan managed to save for a Prusa i3. But firearms were far from his original plan for his new Czech machine. Ivan’s newest car is “like 35 years old” and “there’s little interior bits – plastic parts – that are getting brittle to the point that they’re going to crack from heat and UV exposure over the years.” Looking at the price of restoration parts for his Corvette, Ivan realized that he could save a pile of cash by making the parts himself. The project to print a wholly new interior was a success, complete with fiberglass finishing and original paint the parts were “almost indistinguishable from the original plastic in the car.”

From Cars to Guns

Like many in the community, Ivan points to Defense Distributed’s Cody Wilson as an early inspiration for his leap into 3D printed firearms. He saw the Vice documentary on Wilson’s work and with no projects lined up to print, decided to try his hand at printing an AR-15 lower out of ABS. ABS was the material of choice for his car projects, largely thanks to its heat resistance, but it’s notorious for warping. Ivan tried seven or eight times to get one that “wouldn’t warp terribly.” Ultimately, he succeeded by placing his printer in a closet with a space heater to keep the environment warm enough to prevent warping. It may not have been the safest approach, but the result was Ivan’s first functional 3D printed gun part – a FOSSCAD V5.1 two-piece AR-15 lower receiver.

Not entirely confident that the lower would be safe to use, Ivan paired the FOSSCAD lower with a bargain basement Palmetto State Armory kit and took it out to his backyard range. To his surprise, the lower withstood a full 30-round magazine without issue. “This is like unlimited power… If it lasts 30 rounds and I now have a way to repeatedly make these things, I’ve made it” Ivan recalled thinking as he stood over his successful build. With a magazine’s worth of ammo under its belt, Ivan took the lower back into the shop and gave it an acetone dip. Acetone is known to dissolve ABS, but dipping parts briefly in the solvent helps to smooth the outer appearance of printed parts and more importantly, improves interlayer strength along the part’s Z-axis. Ivan figured the process would help to prevent future splitting between printed layers on his receiver. The receiver would then go on to fire over 2,100 rounds before small cracks at the front takedown pin and the buffer tower led Ivan to retire the part.

Early Designs

While the FOSSCAD AR-15 lower was a success, Ivan felt it could be improved. Shortly after his intial successful print, he posted his modified design to Reddit. Redditors questioned its practical durability. “At one point I posted that lower to the firearms and guns subreddit… Some of the feedback I got was ‘unless you can do rifle pushups on this thing or you can mortar it and drop or fall on it, it isn’t much more than a range toy’” was a common critique. He didn’t appreciate the feedback at the time, admits now that the criticism was valid.

Beyond the AR lower modifications, Ivan didn’t plan to jump headlong into 3D printed firearms development. His thinking was largely, “I essentially wanted to shitpost on Twitter, especially to people who said AR lowers only last 30 rounds.” The tendency of people to both oversell and undersell the capabilities of printed firearms and parts pushed Ivan to take to social media, where in addition to regular debunkings of such claims, you’ll find plenty of video evidence supporting his development and testing efforts.

Printable Magazines

“Not to slight Defense Distributed’s work, because it has to be understood that most of what their work has been is fighting legal battles… but the documentation side of things was absolutely awful.” The original printable magazines created by Defense Distributed weren’t provided with any sort of information regarding the type of printer or settings to use. Though he eventually determined that Defense Distributed used laser and resin-based SLA machines to print their magazines, the poor documentation led Ivan to take the printable AR-15 magazine on from scratch.

“PLA didn’t work. ABS didn’t work. PETG didn’t work.” Quickly, Ivan discovered that the trio of popular printing materials simply wouldn’t cut it in an AR magazine. The lips were just too weak. “So I turned to a couple different kinds of nylon. The first nylon I used was Kodak’s 6-6 nylon… and while it was awfully strong, it was way too flexible for an AR mag.”

“I had found people hypothesizing that DuPont or that Magpul is using DuPont Zytel to make the PMAGs. So I found DuPont sells their filament… It’s a hundred dollars a kilogram. I decided to get a roll of that and see… Wouldn’t you know, the first magazine I print with that holds down 30 rounds and feeds 30 rounds,” Ivan said.

Ivan wasn’t entirely satisfied with the performance of the AR magazine, even with the expensive Zytel filament. He hypothesized that the Defense Distributed design’s guide rails weren’t optimized for printing. Recounting his modifications, Ivan said, “I [made] a couple small geometric [changes] in the magazine rails that guide the neck of the cartridge. I made it so they’re more like a PMAG. The Defense Distributed magazine had it so they’re placed like they are on GI mags but I moved that back to sort of where PMAGs were… I don’t pretend that they’re perfect… But there’s at least a chance that they run reliably, which is an improvement.”

The AR magazine project led Ivan to some methodological breakthroughs that would serve him well later, particularly during development of his printed Glock magazine (dubbed the “Menendez Magazine” after anti-gun New Jersey Senator Bob Menendez, who pressured Twitter to ban Ivan over his AR-15 work).

“[Y]ou can use a soldering iron to remelt the layers of your printed part and that sort of alleviates the fact that the z-axis is as weak as it is… Because any time that cracks open up on your z-axis is from between layers… If you can fuse those layer lines together, your part approaches injection molded strength,” Ivan said. He recalled, “with untreated mags, I was getting about 200 rounds before the lips cracked off… with treated mags, I’ve still got two magazines that are like four or five hundred rounds each and I haven’t managed to break off [their lips].”

If magazines simply consisted of a plastic box, Ivan would have been done there. But they’re a bit more than that and importantly, you can’t directly print the needed internal spring. “I had made a jig that you could wind a spring wire around and then… you use some sort of metal clamp to hold the spring wire in its shape… Then take it off the mandrel [and] bake it in the oven [for] stress relief. Then you’ve got yourself a homemade magazine spring,” Ivan recounted. Remarkably, the DIY magazine spring works perfectly in existing factory magazines without issue.

“The whole time I was doing this project, people were telling me, ‘Okay what about magazine springs?’ and so that was sort of my first foray into people telling me, ‘But what about this?’ and then me showing you, well, it’s not that difficult,” Ivan said.

Glock Frames

“There was there was the guy who had posted what he was calling the Banana Standard Glock to Reddit. He’s calling it the first 9mm Glock [ever] printed… So then there was a guy who had been following me on Twitter who just DM’ed me out of the blue and he said, ‘that’s not the first printed Glock 9mm.’”

That’s how Ivan’s work on printed Glock frames got its start. “[the Twitter follower] sends me this video of him shooting and he’s kicking nine mils out of this printed Glock frame and I’m sitting up there looking at it like ‘well you know here you go’ and ‘how have I not heard of this?’. That individual takes a screen name of FreeMenDontAsk.”

When the developer of the Banana Standard decided against releasing his files, Ivan and FreeMenDontAsk vowed to release their own, improved design. Unfortunately, FreeMenDontAsk’s PC failed catastrophically in the interim, leaving the pair with a much earlier version of the Glock frame.

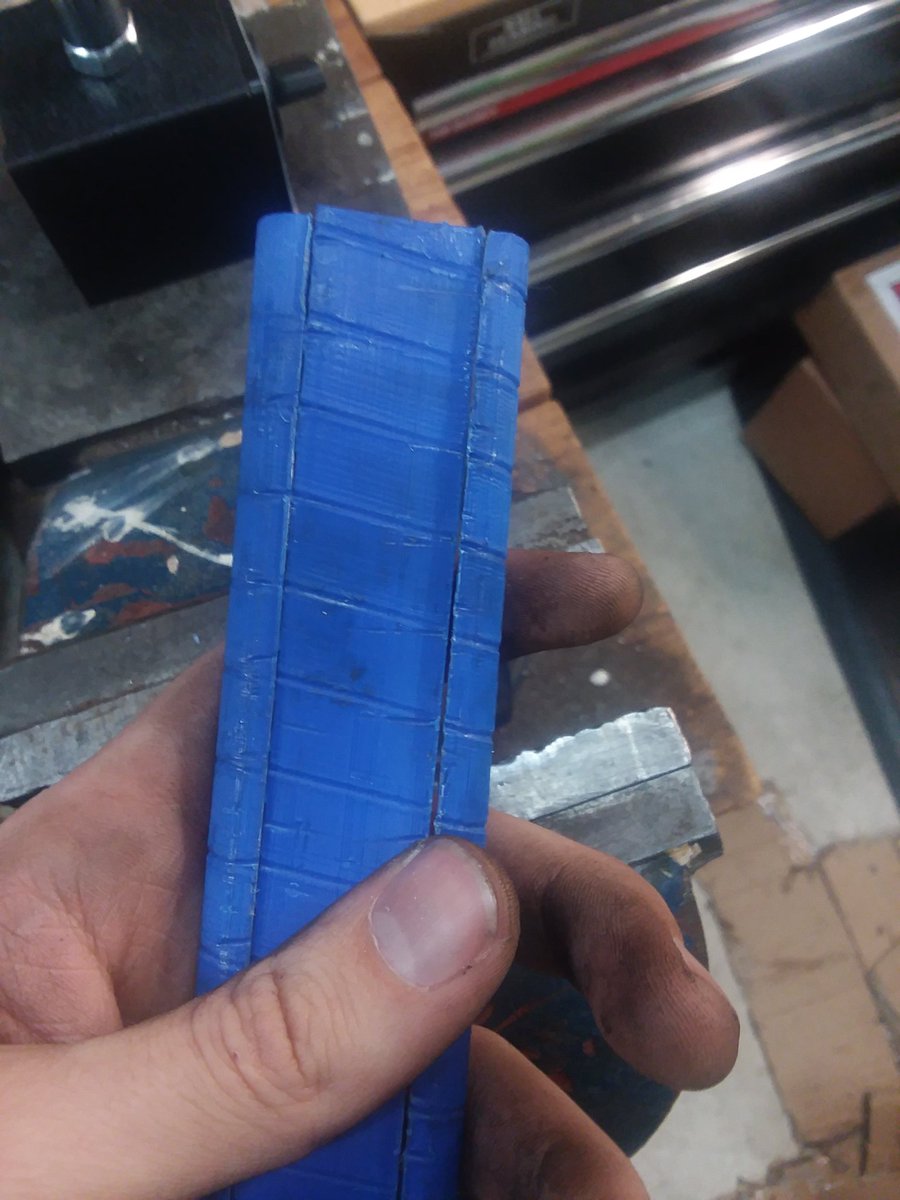

Ivan recalled that one of the major challenges with the design was the frame’s slide rails. “On the original frame he had done, he had just printed the rails and you had a couple hundred rounds on printed rails. That way we replicated the fact that printed rails do actually work fairly well. It ends up being the front rail that overheats because it’s right underneath the chamber… So we decided we were going to re-spec to aluminum because of course that’ll hold up a lot better. So we went through the new the agony that was sort of finding the correct spec.”

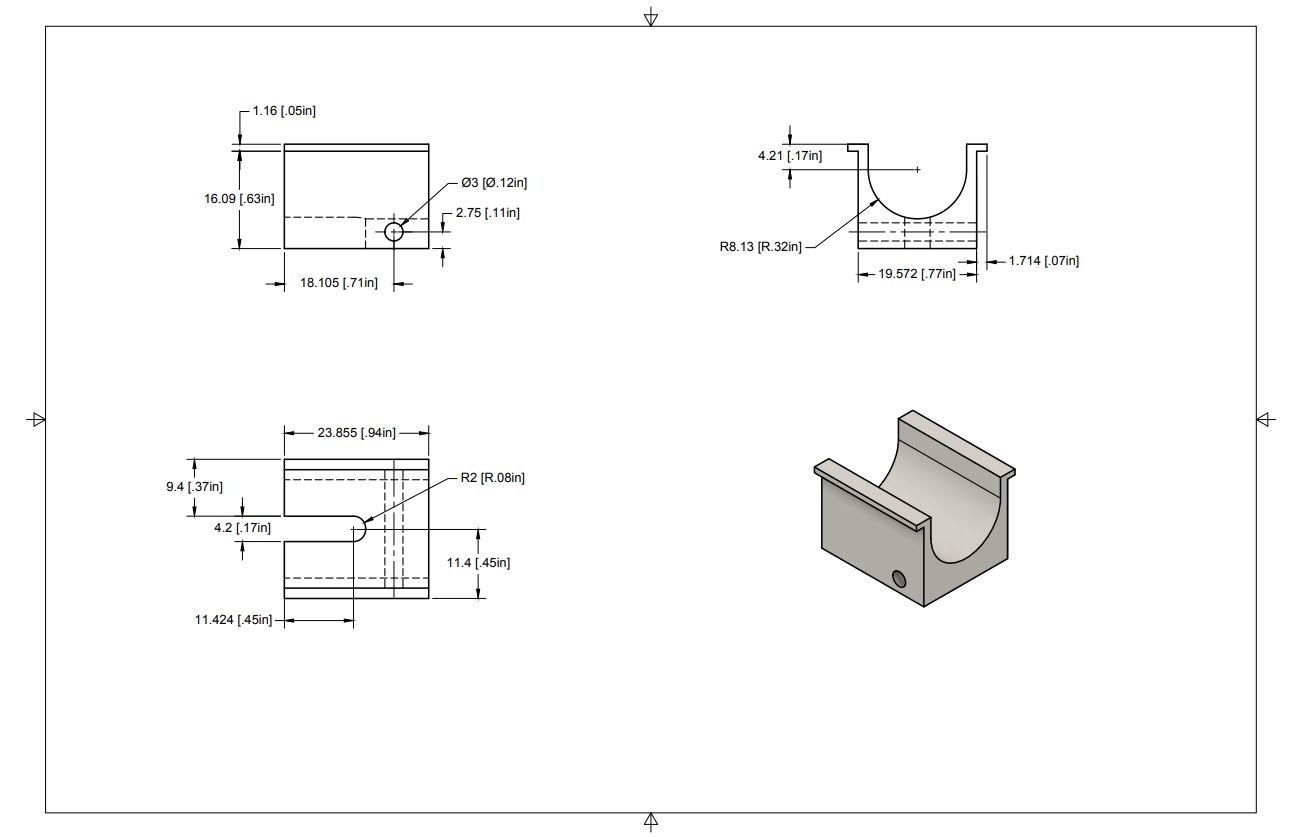

After several rail revisions, Ivan and FreeMenDontAsk eventually reached a workable design. In contrast with Defense Distributed’s documentation, Ivan’s files come with detailed instructions outlining print settings and assembly with the intent that someone with very little (no more than a week of printing experience) could turn out a functional pistol on a $200 printer, like Creality’s Ender-3. Even so, the challenge remained. How were people going to manufacture aluminum rails? For that, Ivan’s response was simple: print a jig and use hand tools. The end result was a design simple enough to be printed by someone with less than a week of printing experience.

Wrapping Up

In part two of this series, we’ll take a look at more recent developments from Ivan and others in the 3D printing community, including the semi-automatic 9mm FGC-9 along with barrels made using printed tooling. We’ll also discuss the future of printed firearms and parts.

An information security professional by day and gun blogger by night, Nathan started his firearms journey at 16 years old as a collector of C&R rifles. These days, you’re likely to find him shooting something a bit more modern – and usually equipped with a suppressor – but his passion for firearms with military heritage has never waned. Over the last five years, Nathan has written about a variety of firearms topics, including Second Amendment politics and gun and gear reviews. When he isn’t shooting or writing, Nathan nerds out over computers, 3D printing, and Star Wars.