How To: Convert a Saiga to AKM Configuration

Over the past two or three years, I have seen several collectors asking about the feasibility of converting a Russian Saiga 7.62x39mm rifle to AKM configuration. As a sporting style rifle that has been built on an AK-100 series action, turning back the clock on the Saiga is no simple task. However, as someone who has nearly completed this time travel journey, I can say that it is absolutely possible to make an AKM out of a Saiga and the end result can be very rewarding.

If you’ve done a standard Saiga back end conversion before, the process is no different for the AKM conversion. To begin, simply drill out the old trigger pins, remove the riveted plate that covers the AK trigger hole, and remove the trigger guard. If you are lucky, the square hole for the pistol grip nut will already be cut. If it is not make necessary measurements (approximately 2 millimeters forward of the old trigger hole) and I recommend tracing a pistol grip nut as a guide for the hole itself. Cutting the hole can be done with a Dremel if you are careful and go slowly. I also recommend removing the magazine release and obtaining a proper AKM unit, which can be riveted through the same holes as the original Saiga part. While it is possible to retain the original trigger guard and either weld it to the magazine release or feed its previously riveted foot underneath the original magazine release, replacement is far and away the cleanest option. Once this back end conversion is complete, weld up the resulting holes for a cleaner look. I used a Tapco G2 AK trigger with a retaining plate for the pins in my conversion and like this configuration very much.

Those looking for a proper AKM clone should remove the optics rail. AKMNs weren’t/aren’t very common, so if you do not plan on using optics and want a true AKM replica, remove the rail. Furthermore, the Saiga optics rail is a much more modern version than what would be found on an AKMN. I have not had this done to my rifle yet, but plan to have the rail removed at the same time I have the conversion holes welded.

Two of the simplest changes for this project are swapping the receiver dust cover and rear sight leaf for original AKM parts. I purchased both of these parts from Oleg at Rusmilitary.com and both are original Soviet examples. Removing the rear leaf can be challenging, but I have had success using a screwdriver to push the front portion of the part down while pulling it out from the rear. Installing the new one can be accomplished by firmly pushing it in from the rear through the channels cut into the sides of the rear sight block. This step may not be necessary if you plan to replace the whole rear sight block with a proper AKM one. The main difference between the Saiga rear sight block and an AKM one is the chamfer that surrounds the sight leaf. Most people will not notice this unless they are actively looking for differences. The dust cover should go on just like the original part, however I have found some new-old-stock Soviet dust covers are a tight fit compared to the Saiga’s. Fortunately, this stamped steel cover is easily bent to fit.

Like any Saiga conversion, a bullet ramp/guide must be added for the rifle to properly feed from a standard AK magazine. I used a guide from a Bulgarian AK-74 for mine, but the Dinzag Arms version for Saigas is a better choice. Dinzag offers a kit with the proper drill bit and tap to install the ramp, I would go this route if I were doing the conversion today.

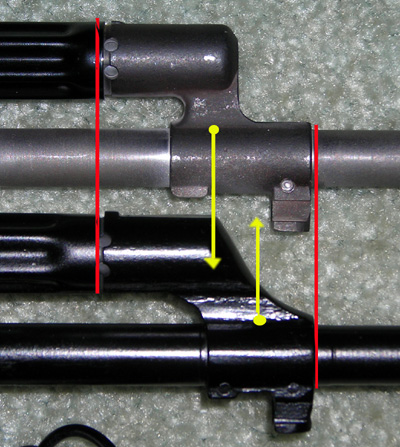

Changing the barrel parts is the most difficult part of the project. Before starting, you will need an AKM front sight block, a 45-degree AKM gas block, an AKM handguard retainer, and an AKM rear sight block (optional, for absolute accuracy) . The original barrel parts will need to be pressed off and the new ones pressed on. This is essentially impossible to accomplish without at least a 12-ton press. After all original parts have been pressed off the barrel, press the AKM rear sight block on first. It is reasonably likely that you may be able to use the original pin hole to set this in place. Next, use an end mill or Dremel grinding wheel to cut alignment grooves into the barrel for the handguard retainer. These should be at the 3 and 9 o’clock positions on the barrel, just behind the step where the barrel thickens under the handguard. You should also make a channel for the retainer’s lever at the 12 o’clock position, perpendicular to the barrel, and with a center 5 millimeters behind the step.

After the above steps are complete, the original gas port should be welded closed on the barrel. Placement for the original hole will likely fall just above the rear pin hole in the block. AKMs have a 45-degree port that is drilled just behind the bayonet lug. This means that the two holes are a little over half a centimeter apart. Measure approximately 6 millimeters forward of the original gas port and drill a new one using a 1/8″ cobalt drill bit. I recommend countersinking this hole somewhat to allow for some flexibility in gas block placement. Also note that it is not necessary to drill the gas port at 45-degrees like original AKM barrels, a 90-degree gas port will work fine with the 45-degree gas block. Press the new block on so that the front of it matches the position of the forward edge of the old block. You can check gas port alignment by sticking a pipe cleaner through the hole in the gas block and into the barrel. If the cleaner makes it through into the barrel, your alignment is likely good. Next, drill new holes for the pins and hammer/press them in.

The last major piece to add is the front sight block. The only real consideration here is that you will need 6/10 or 3/5” of space for threading forward of the block. Once you have it pressed on to this depth, put the whole rifle in a vise and check alignment through the rear sight. You can make adjustments using a brass hammer on either side of the front sight block to eliminate cant. The front sight block does not need to be perfectly straight, eyeballing it will usually be sufficient, but it is a good idea to use a level to check your work. Once it is aligned to satisfaction, drill new pin holes and hammer or press the new pins in.

Once all barrel components have been installed, clean up the work by welding the old, now exposed pin holes closed and grinding the welds flush. Threading the barrel is an easy home job using the 14×1 AK threading kit from CNC Warrior. This kit includes a die, thread alignment tool, die handle, and cutting oil. Beginning the threading process is as simple as partially screwing the alignment tool into the die and sticking the alignment post into the muzzle. As the die is rotated around the barrel, the alignment tool will eventually be backed off the rear of the die. Do not thread the barrel too quickly; after each 1/4-1/2 twist of progress, the die should be partially backed off and metal shavings should be cleared from the tool and the barrel. Make sure to use plenty of oil to prevent binding. The whole process can be summarized as twisting the die on a little, backing it off a little, and twisting it back on a little further repeatedly until the 6/10” of exposed barrel has been fully threaded. Once complete, add a slant brake and you are done.

After the barrel is complete, obtain a correct AKM or AK-74 style gas tube with handguard. I like to add this part towards the end of the project because fitting will be required to get the spacing correct for the new gas block and rear sight block. There are flat surfaces on the rear of the gas tube that can be filed to fit the piece if it is too tight and cannot be pushed or lightly hammered into the rear sight block. The gas tube should fit into the front of the rear sight block relatively easily, but should not rattle.

After all the conversion work is complete, purchase a set of AKM furniture. I highly recommend real Soviet wood from somewhere like Rusmilitary.com, but availability can be spotty. Ironwood Designs does an adequate job of replicating Russian AKM wood with real arctic birch laminate if authentic parts are not available. Any AKM or AK-74 cleaning rod will work for this project.

That is pretty much all there is to converting a Saiga to an AKM clone. On my rifle, I went to extra lengths to ensure that as many of the new parts were original Soviet examples. Outside of 922(r) compliance parts, the only non-Soviet part on my rifle is a Romanian handguard retainer. Since I wanted to replicate a late-1970s AKM, I sought a cast Izhmash gas block and cast front sight block with a squared lightening hole. Cope’s Distributing has recently had some complete rear sight assemblies and trigger guards that originally came from Soviet AKMs. My laminate furniture came from another collector and is unissued Soviet replacement wood. For those wondering, my compliance parts are my muzzle brake, gas piston, trigger parts, and magazine follower.

While the Saiga to AKM conversion process is highly involved and perhaps more difficult than simply building an AKM from the ground up, I feel it was a worthwhile endeavor. The conversion allows me to retain the original Russian cold hammer forged barrel and Izhmash receiver, both of which are excellent quality parts and really are the heart and soul of the firearm. I will concede that the rifle is not 100% accurate in terms of rivet placement, bolt carrier profile, dimples (or lack thereof), and a few other minor differences, but these should not detract from what is a very nice example on the whole. Having begun back in 2008, this project has certainly been time consuming and has taken extensive help from AK experts, but the end result is something I am truly proud of and is a centerpiece of my collection.

An information security professional by day and gun blogger by night, Nathan started his firearms journey at 16 years old as a collector of C&R rifles. These days, you’re likely to find him shooting something a bit more modern – and usually equipped with a suppressor – but his passion for firearms with military heritage has never waned. Over the last five years, Nathan has written about a variety of firearms topics, including Second Amendment politics and gun and gear reviews. When he isn’t shooting or writing, Nathan nerds out over computers, 3D printing, and Star Wars.