A Behind the Scenes Look at St. Croix Rod Technology

St. Croix is known for producing quality rods while keeping them at a price that appeals to a broad audience. They’ve been handcrafting fishing rods in Park Falls, Wisconsin, for 72 years while owned by the same family for the past 43 years. Long time St. Croix anglers might tell you the rods are durable and deliver sensitivity while also providing the power needed to reel in the big ones. So how does St. Croix produce a rod that offers high performance but at an affordable price? Jason Brunner, Director of Operations, says it’s a combination of science and pride.

According to Brunner, St. Croix’s rod-building process begins with a commitment to seek out and use advanced materials to bring out the best qualities in every model. “Investing in emerging composite materials and innovating the latest manufacturing processes, we have created many of the industry’s biggest performance breakthroughs and continue to explore new ways to make fishing better,” Brunner says. “Lighter, stronger, and more responsive rods all begin with these advancements.”

Carbon Materials

The company’s SC carbon materials (SC stands for St. Croix), levels II through VI, each feature an increasing modulus (stiffness of the graphite fibers) and variable strain rate (how far carbon fibers stretch before failing), allowing St. Croix to fine-tune each rod to match design specifications and pricing considerations.

St. Croix’s SCII Premium carbon material features mid-modulus graphite fiber with a higher strain rate than fibers commonly used by other rod manufacturers. An excellent choice for anglers who appreciate high performance without the high cost. You’ll find these materials in the Triumph, Premier, Bass X, Eyecon, Panfish and Trout series, and some Mojo series rods.

SCIII Advanced carbon material features high-modulus, high-strain carbon fibers. It’s used to produce sensitive, lightweight, and durable rods like those found in the Mojo Bass, Mojo Musky, Avid, and Avid X rod series.

In addition to St. Croix’s carbon blank materials, the company also employs premium 100% linear S-glass in rods that require moderate actions or forgiving tips, such as those used in crankbait or trolling applications. This material is stronger and lighter than ordinary E-glass, and delivers the full benefits of linear fiberglass such as strength and forgiveness, plus elevated feedback, increased strength, action, reduced weight. This material is found in Legend Glass, one of St. Croix’s most popular rod series, as well as Mojo Bass Glass, and blended with SCII carbon in Eyecon Trolling and Mojo Musky Trolling rods.

Technology

St. Croix considers choosing materials with focus and using only the best is a great start. But they refine them further by using proprietary technologies developed through its suppliers, design team, and manufacturing experts over the years. These technological advancements increase performance and quantifiable factors like sensitivity, durability, and strength across the company’s entire lineup.

“We have several high-tech technologies and manufacturing processes we can use or combine to bring out the best qualities in any rod blank we manufacture,” continues Brunner.

“In fact, through the years, we’ve developed a program that can factor in many of our variables and give us a solid indication of how any rod we plan to design will perform over a variety of qualities before we even build it. We’ve learned and charted over the years exactly what it takes to make anything from an ultra-light to a medium or extra-heavy rod power. We can assign rod action specifics from extra-fast to slow, determine the exact weight of the rod, factor in the effects of specific individual components, increase the durability and adjust the price point appropriately, all before building our first samples. All this information is provided to the manufacturing team to take the guesswork out of the rod-building process. The result is that, from the very first prototype of any new design, we are generally close enough to the desired performance that many projects only require a few small modifications to reach perfection.”

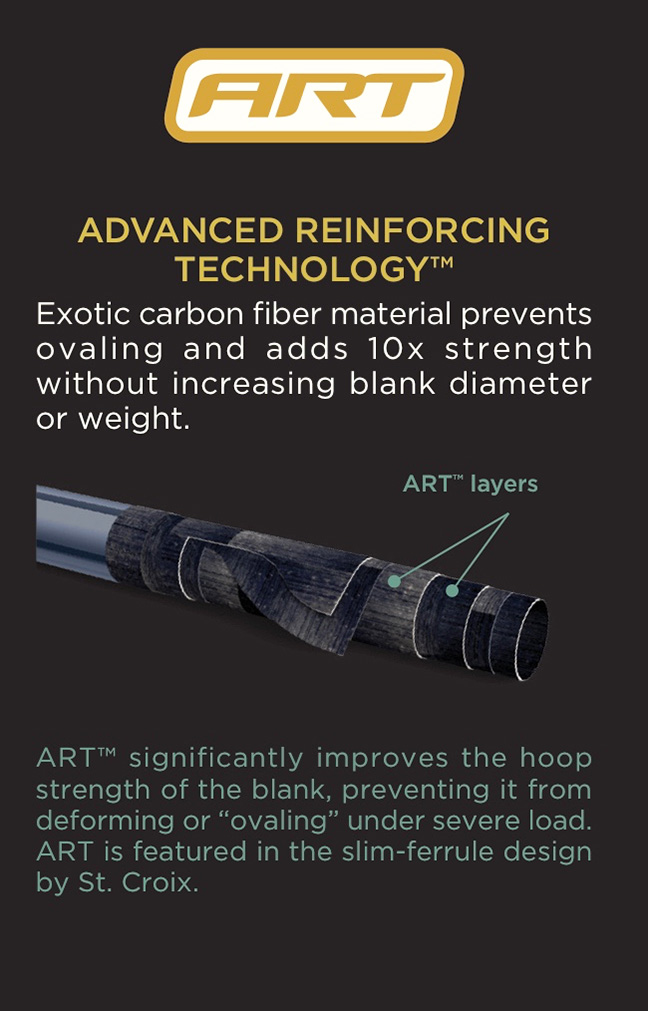

Advanced Reinforcing Technology™ (ART™) uses an exotic carbon fiber material that adds a magnitude (10X) of strength with virtually no increase in blank diameter or weight. It significantly improves the hoop strength of the blank by preventing it from deforming or “ovaling” under severe loads, such as a those experienced during a powerful hook set or when lifting a heavy fish. ART is also a critical part of St. Croix’s slim-profile ferrule design.

St. Croix’s FRS (Fortified Resin System) combines a fortified super resin with new computer-operated curing ovens that provide improved temperature and time management through all stages of the critical curing cycle. FRS prevents micro-buckling by keeping the carbon fibers in proper alignment. Blanks manufactured using this advanced manufacturing protocol consistently test 33% stronger than those built with standard resins and curing methods.

Taper Enhancement Technology (TET) is a process perfected by St. Croix. It begins with precision-cut, curved blank patterns made possible by a computerized pattern cutting machine. When combined with IPC-mandrels, these patterns create blanks with better actions and improved sensitivity. This pattern design and cutting technology is a dramatic departure from traditional straight-line patterns cut by hand.

Manufacturing

For St. Croix, building the ideal fishing rod involves a serious amount of science and technology, but their philosophy is, none of it matters unless the entire team is on board. And that they say, is what sets them apart.

I grew up in Canada, but unfortunately, I did not take advantage of shooting or hunting when I lived there. I just didn’t grow up with it, but I did fish a lot. It’s only after I joined a firearm company that I could reap the benefits of having great mentors teach me the ropes. Now I’m hooked and want to experience everything I can! So much so, I was compelled to co-found this site. I hope you enjoy it, and all feedback is welcome.